MILLCHOC ball mill

Ball mill for the production of confectionery and chocolate icing

The ball mill is designed for the preparation of liquid and pasty products (hereinafter mixtures) by mixing and grinding (confectionery icing, paste) and consists of a ball mill, a premixer, an icing feed pump and a control cabinet.

Application – confectionery, pharmaceutical, cosmetic, chemical and paint companies.

How it works

The shaft (rotor) is located inside the vertical cylinder (stator). Special shaped pins are fixed on the outer surface of the rotor. The product is pumped into the grinding chamber from below, passes through the space between the rotor and the stator, filled with metal balls driven by the rotor pins.

Under the influence of continuously colliding and rubbing balls against each other, the solid particles of the processed product are crushed and abraded. Passing through the grate located at the outlet, the finely divided product is separated from the balls and fed to further processing.

All parts of the unit in contact with the processed product are made of special steel.

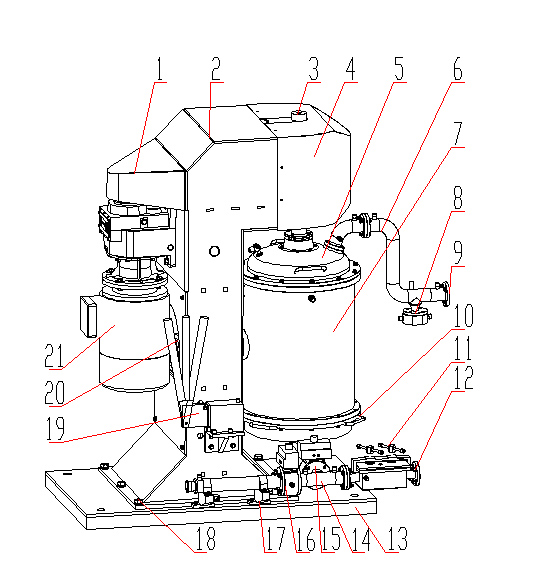

Ball mill (axonometric view):

1- ball mill drive casing;

2 – plate;

3 – shaft washer;

4 – casing;

5 – top cover;

6 – product circulation pipeline;

7 – horizontal reservoir with a volume of 190 l;

8 – tap for sampling in heating;

9 – flange connecting to the premixer;

10 – top flange;

11 – filter;

12 – connecting flange;

13 – base;

14 – intermediate pipeline;

15 – ball valve in heating;

16 – ball valve in heating;

17 – pipeline bracket;

18 – bolt fixing the plate to the base;

19 – hydraulic hand pump for turning ball mill;

20 – hydraulic cylinder;

21 – agitator drive.

Model specifications:

| Model | Capacity, kg / h | Cycle period, h | Power, kVT |

| MILLCHOC-500 | 150 | 3-4 | 18 |

| MILLCHOC-1000 | 300 | 3-4 | 32 |